Building Collaboration: Hyparvilion

Project Details

date

process

Summer 2024

Team project: Rhino 7, Various Fabrication and Construction methods

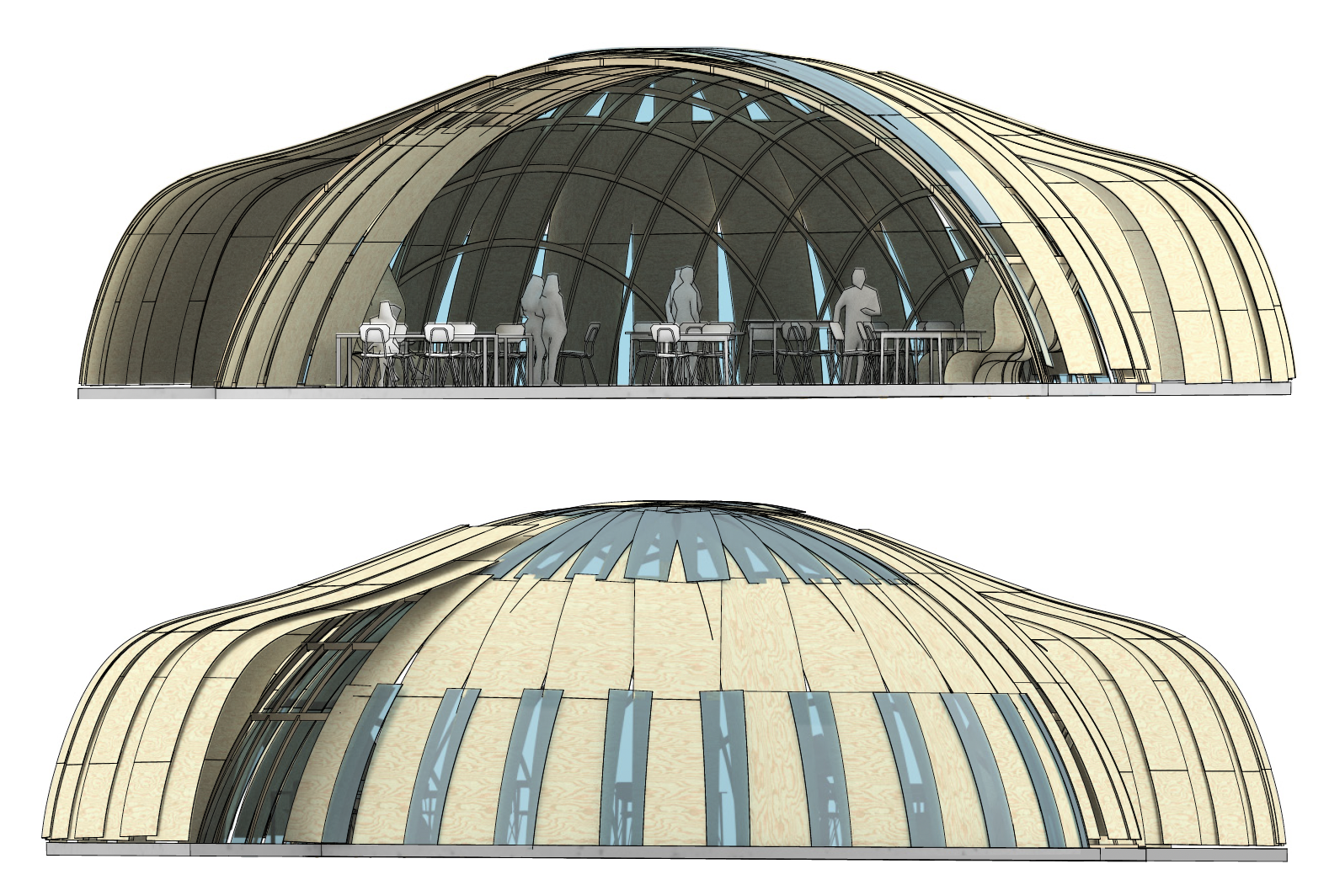

The 2024 Design Build Studio Pavilion was designed for the President of the University in order to showcase the potentials of a gathering event space in between the LTU Alumni House and the President’s House. The course is structured as a series of assignments which progressively increase in scale and complexity. Students begin in small groups of 5-7 individuals who explore a single precedent. Through the investigation of user interaction, material use, tectonic design, and site exploration, the team culminates in a pavilion proposal for a specified site. As the assignments progress, the teams are merged together and then incorporate each the outcomes of each team into a new design. The concluding project pulls together four initial team projects into one final design.

The final design is then constructed on campus over a span of one week by its designers.

PROJECTS 01 & 02

PROJECTS 01 + 02 begin by introducing students to their group’s precedent. Project 01 was a short week and a half long research and design process which quickly immerses students into the class’s format. The team strategies and design processes which were developed in PROJECT 01 were then deployed throughout the semester. PROJECT 02 introduces the element of collaborative work between teams. By taking two groups and merging them together, student’s had to unite ideas, design tectonics, and materials in order to create a formally resolved design which could form to the site without being repetitive. The teams had to design potential connections and bring feasibility into account when designing in PROJECT 02. As the projects progressed, more design iteration took place to ensure the connection strategies that were proposed would work structurally with the design.

01

TEAM

Dane Peterson, Alexandra Biancofiore, Alyssa Dempsey, Trinidad Martinez, Jacquelin Syegco, Trevor Werthmann

My Contributions

Designing and modeling the polycarbonate cladding modules

02

TEAM

Dane Peterson, Alexandra Biancofiore, Alyssa Dempsey, Trinidad Martinez, Jacquelin Syegco, Trevor Werthmann, Allison Clark, Jordan Currier, Jared Roberts, Eduardo Sanchez, Ibrahim Shuwayah, Faith Ten-Eyck

My Contributions

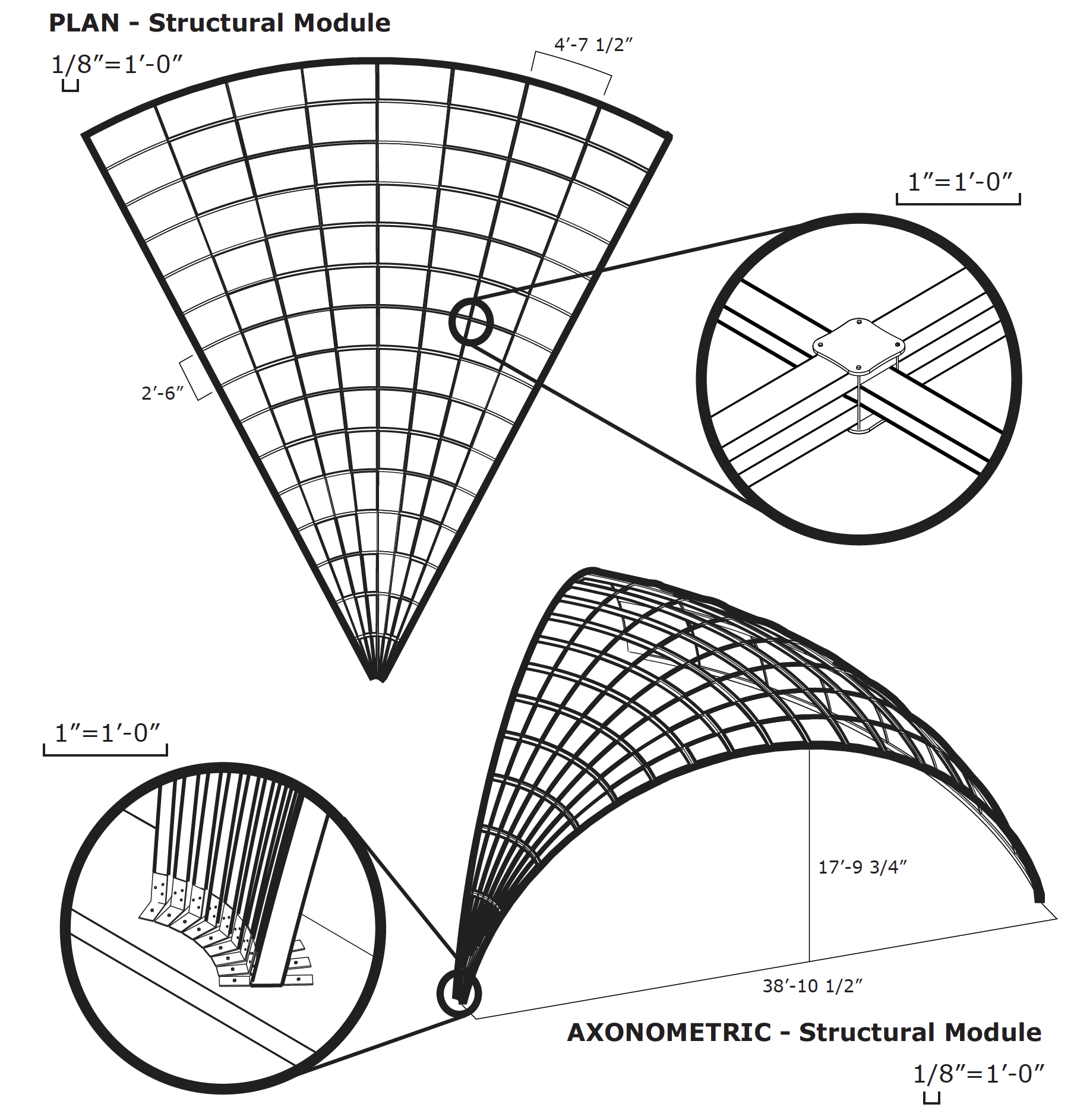

Designing and modeling the structure of the pavilion

PROJECT 03

In the culmination of Design Build Studio, PROJECT 3, we were combined into our final groupings and asked to hybridize and advance our designs from PROJECT 02 into a newly refined and buildable structure. This resulted in a team of 26 students, which was then split into smaller sub-teams in order to create focus groups specializing in each area. These teams worked together to create models, connection details, and drawings, all working towards the final product. We worked to ensure the design kept the morphing, living nature of the previous designs while engaging with the realities of construction to allow the new form to be feasibly built. This means the pieces were carefully placed in order to support and interlock together to form the final outcome. The final form created is a collection of hyperbolic paraboloid roofs supported by a series of lattice walls. The name of the final project is derived from the form: The Hyparvilion.

TEAM

Dane Peterson, Alexandra Biancofiore, Alyssa Dempsey, Trinidad Martinez, Jacquelin Syegco, Trevor Werthmann, Allison Clark, Jordan Currier, Jared Roberts, Eduardo Sanchez, Ibrahim Shuwayah, Faith Ten-Eyck, Ian Barrowclough, Autumn Hendrickson, Alexandra Hernandez, Aaron Isyk, Daniel Mackowiak, Autumn Maley, Matthew Malski, Rob Misiag, Robin Scott, Katlynn Singleton, Heather Soper, Jack Stibal, Aaron Stunson

My Contributions

Designing and modeling construction details (mainly the hidden plate connections), graphic representation, material testing

Portion to be physically built

Hidden Plate Connections

This custom connection detail takes two 1/4” steel plates that are welded together, sandwiches them between sistered 2x10 beams, and slots them into the top of a 4x4 column. This detail hides the hardware and provides a strong, flush connection between the beam and the column.

Using this custom connection instead of typical strong-tie connections allows the structural expression of the form to remain uninterrupted by store-bought hardware that could detract from the aesthetic.

PROJECT 04: Build Week

Photo documentation by professional photographer Steve Kroodsma

The Team